In the ECONOMIC Order Quantity the whole inventory order was placed at one time, instantaneously raising the stock levels. This situation is typical of wholesalers who operate with large inventories, large quantities, and large turnovers. However in a manufacturing environment, the situation is somewhat different. If a firm’s rate of production is greater than its customer demand, the firm can meet its customers’ inventory requirements on an ongoing basis, while also building up an inventory from surplus stock. When this surplus inventory becomes large enough to meet customer demands for a reasonable period of time, production of the item can stop until all excess stock has been used up. On the other hand, if the production rate falls below customer demand, there will be no surplus goods, and some customer orders may not be fully met.

The production order quantity (PROQ) model differs only from the EOQ model in that replenishment is not instantaneous, otherwise the same conditions hold, i.e.,

A single item is considered.

All costs are known exactly and do not vary.

No shortages (stockouts) are allowed.

Let us have one example:

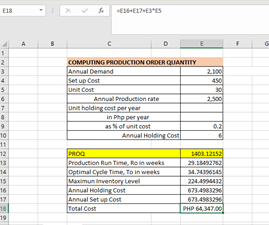

The CADELINA Company manufactures AUTOPARTS with an annual demand of 2100 units. The AUTOPART is manufactured at a rate of 2500 units per year. Unit cost for an autopart is P30, setup cost is P450, and the annual holding cost is 20% of its value. Using the formula template provided at the bottom , create the Production order quantity (PROQ) model, and hence find the optimal batch size, cycle time, and total cost for an Autopart (see cells E12:E18).

No comments:

Post a Comment